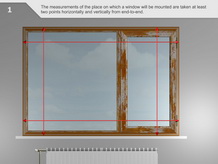

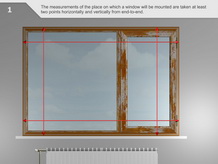

The measurements of the place on which a window will be mounted are taken at least two points horizontally and vertically from end-to-end.

The measurements of the place on which a window will be mounted are taken at least two points horizontally and vertically from end-to-end.  The sashes of old Windows are removed from its hinges.

The sashes of old Windows are removed from its hinges.  Fixed glazings of old window are demounted

Fixed glazings of old window are demounted  First mullion profiles and then edges of the frame is sawn. For preventing grout to be cracked and peeled off, joinery is removed bu pulling it out horizantally and vertically.

First mullion profiles and then edges of the frame is sawn. For preventing grout to be cracked and peeled off, joinery is removed bu pulling it out horizantally and vertically.  Sash and frame glazing beads of new window are removed and grouped as it will not be mixed.

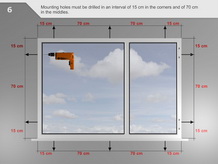

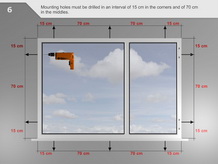

Sash and frame glazing beads of new window are removed and grouped as it will not be mixed.  Mounting holes must be drilled in an interval of 15 cm in the corners and of 70 cm in the middles.

Mounting holes must be drilled in an interval of 15 cm in the corners and of 70 cm in the middles.  During the mounting of frame to the wall, preventing it to be damaged, profiles are drilled with drill tip of 6 mm from end to end.

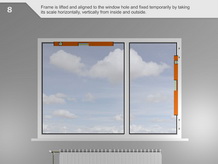

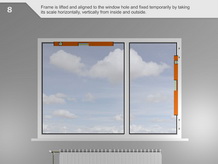

During the mounting of frame to the wall, preventing it to be damaged, profiles are drilled with drill tip of 6 mm from end to end.  Frame is lifted and aligned to the window hole and fixed temporarily by taking its scale horizontally, vertically from inside and outside.

Frame is lifted and aligned to the window hole and fixed temporarily by taking its scale horizontally, vertically from inside and outside.  Through the mounting holes of 6 mm of the frame previously drilled, concrete and walls are drilled with a diamond bit of 5.5 mm.

Through the mounting holes of 6 mm of the frame previously drilled, concrete and walls are drilled with a diamond bit of 5.5 mm.  Through the mounting holes of 6 mm of the frame previously drilled, only upper section of profile is drilled with a bit of 12 mm.

Through the mounting holes of 6 mm of the frame previously drilled, only upper section of profile is drilled with a bit of 12 mm.  Drilling must be performed in a manner that it will be aligned with concrete ducts between bricks. In case screws are aligned with brick holes, it cannot function.

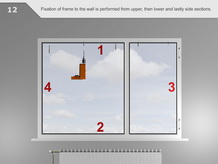

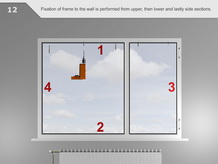

Drilling must be performed in a manner that it will be aligned with concrete ducts between bricks. In case screws are aligned with brick holes, it cannot function.  Fixation of frame to the wall is performed from upper, then lower and lastly side sections.

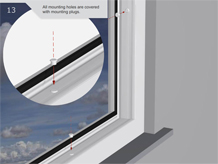

Fixation of frame to the wall is performed from upper, then lower and lastly side sections.  All mounting holes are covered with mounting plugs.

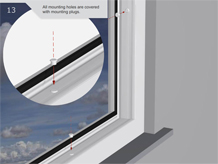

All mounting holes are covered with mounting plugs.  Sash is mounted. For mounting sash glaze, first thick glazing buffers are adhered with silicone to the horizon and vertical of lower hinge corner.

Sash is mounted. For mounting sash glaze, first thick glazing buffers are adhered with silicone to the horizon and vertical of lower hinge corner.  Sash glazing is mounted to its place and first glazing beads of lower section is hammered its place.

Sash glazing is mounted to its place and first glazing beads of lower section is hammered its place.  By wrenching sash up, the clearance in the horizon and vertical of espagnolette corner at upper side is fed with appropriate cleats.

By wrenching sash up, the clearance in the horizon and vertical of espagnolette corner at upper side is fed with appropriate cleats.  Other glazing beads of sash are hammered to their places.

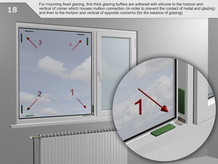

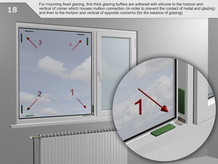

Other glazing beads of sash are hammered to their places.  For mounting fixed glazing, first thick glazing buffers are adhered with silicone to the horizon and vertical of corner which houses mullion connection (in order to prevent the contact of metal and glazing) and then to the horizon and vertical of opposite concerns (for the balance of glazing).

For mounting fixed glazing, first thick glazing buffers are adhered with silicone to the horizon and vertical of corner which houses mullion connection (in order to prevent the contact of metal and glazing) and then to the horizon and vertical of opposite concerns (for the balance of glazing).  Fixed glazing is mounted to its place

Fixed glazing is mounted to its place  All glazing beads of fixed glazing side are hammered to their places.

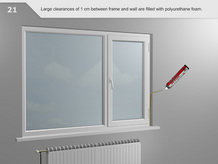

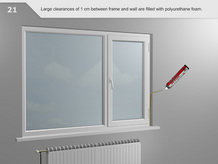

All glazing beads of fixed glazing side are hammered to their places.  Large clearances of 1 cm between frame and wall are filled with polyurethane foam.

Large clearances of 1 cm between frame and wall are filled with polyurethane foam.  The corners on which window and wall are intersected are covered by applying silicone mastic from inside and outside.

The corners on which window and wall are intersected are covered by applying silicone mastic from inside and outside.

The measurements of the place on which a window will be mounted are taken at least two points horizontally and vertically from end-to-end.

The measurements of the place on which a window will be mounted are taken at least two points horizontally and vertically from end-to-end.  The sashes of old Windows are removed from its hinges.

The sashes of old Windows are removed from its hinges.  Fixed glazings of old window are demounted

Fixed glazings of old window are demounted  First mullion profiles and then edges of the frame is sawn. For preventing grout to be cracked and peeled off, joinery is removed bu pulling it out horizantally and vertically.

First mullion profiles and then edges of the frame is sawn. For preventing grout to be cracked and peeled off, joinery is removed bu pulling it out horizantally and vertically.  Sash and frame glazing beads of new window are removed and grouped as it will not be mixed.

Sash and frame glazing beads of new window are removed and grouped as it will not be mixed.  Mounting holes must be drilled in an interval of 15 cm in the corners and of 70 cm in the middles.

Mounting holes must be drilled in an interval of 15 cm in the corners and of 70 cm in the middles.  During the mounting of frame to the wall, preventing it to be damaged, profiles are drilled with drill tip of 6 mm from end to end.

During the mounting of frame to the wall, preventing it to be damaged, profiles are drilled with drill tip of 6 mm from end to end.  Frame is lifted and aligned to the window hole and fixed temporarily by taking its scale horizontally, vertically from inside and outside.

Frame is lifted and aligned to the window hole and fixed temporarily by taking its scale horizontally, vertically from inside and outside.  Through the mounting holes of 6 mm of the frame previously drilled, concrete and walls are drilled with a diamond bit of 5.5 mm.

Through the mounting holes of 6 mm of the frame previously drilled, concrete and walls are drilled with a diamond bit of 5.5 mm.  Through the mounting holes of 6 mm of the frame previously drilled, only upper section of profile is drilled with a bit of 12 mm.

Through the mounting holes of 6 mm of the frame previously drilled, only upper section of profile is drilled with a bit of 12 mm.  Drilling must be performed in a manner that it will be aligned with concrete ducts between bricks. In case screws are aligned with brick holes, it cannot function.

Drilling must be performed in a manner that it will be aligned with concrete ducts between bricks. In case screws are aligned with brick holes, it cannot function.  Fixation of frame to the wall is performed from upper, then lower and lastly side sections.

Fixation of frame to the wall is performed from upper, then lower and lastly side sections.  All mounting holes are covered with mounting plugs.

All mounting holes are covered with mounting plugs.  Sash is mounted. For mounting sash glaze, first thick glazing buffers are adhered with silicone to the horizon and vertical of lower hinge corner.

Sash is mounted. For mounting sash glaze, first thick glazing buffers are adhered with silicone to the horizon and vertical of lower hinge corner.  Sash glazing is mounted to its place and first glazing beads of lower section is hammered its place.

Sash glazing is mounted to its place and first glazing beads of lower section is hammered its place.  By wrenching sash up, the clearance in the horizon and vertical of espagnolette corner at upper side is fed with appropriate cleats.

By wrenching sash up, the clearance in the horizon and vertical of espagnolette corner at upper side is fed with appropriate cleats.  Other glazing beads of sash are hammered to their places.

Other glazing beads of sash are hammered to their places.  For mounting fixed glazing, first thick glazing buffers are adhered with silicone to the horizon and vertical of corner which houses mullion connection (in order to prevent the contact of metal and glazing) and then to the horizon and vertical of opposite concerns (for the balance of glazing).

For mounting fixed glazing, first thick glazing buffers are adhered with silicone to the horizon and vertical of corner which houses mullion connection (in order to prevent the contact of metal and glazing) and then to the horizon and vertical of opposite concerns (for the balance of glazing).  Fixed glazing is mounted to its place

Fixed glazing is mounted to its place  All glazing beads of fixed glazing side are hammered to their places.

All glazing beads of fixed glazing side are hammered to their places.  Large clearances of 1 cm between frame and wall are filled with polyurethane foam.

Large clearances of 1 cm between frame and wall are filled with polyurethane foam.  The corners on which window and wall are intersected are covered by applying silicone mastic from inside and outside.

The corners on which window and wall are intersected are covered by applying silicone mastic from inside and outside.